Our interest in blasting developed from our Swindon based engineering business. With many years in building, modifying and tuning speedway and grasstrack racing engines we came across this process as an ideal way to clean and prepare engines for our customers.

Vapour blasting was ideal for our needs as it provided a way to clean badly contaminated and baked-on material without damaging or removing metal. Also known as “Wet Blasting” or “Aqua Blasting”, we can use this process to clean most non-ferrous metals & plastics & ceramics.

What processes do you offer?

We offer a range of processes which we can combine depending on your requirements, time lines and budgets.

Vapour Blasting

Using a combination of high pressure water and detergents we can clean and degrease parts saving hours or work with great results.

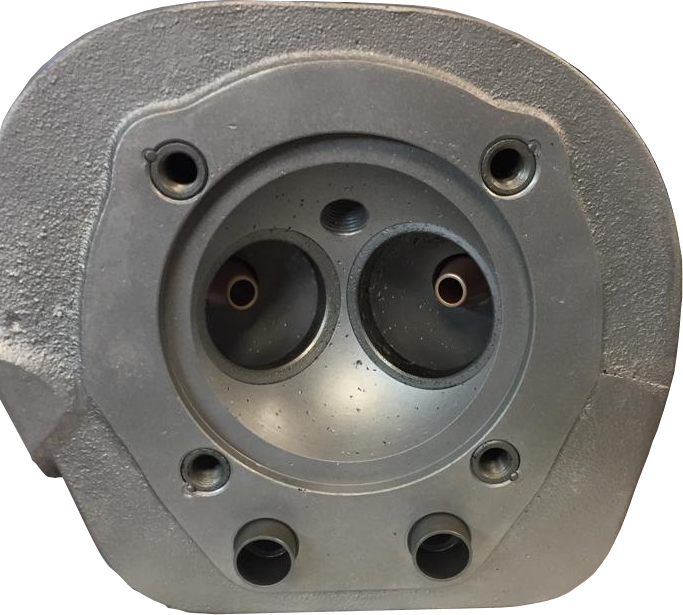

This process is great for enineering surfaces where tolerances are crucial. For example in an engines’ cylinder head the “mating” face beween valve and valve seat is crucial. We “gas tested” a cylinder head both before and after blasting, the valves sealed just as well after with no additional work!

Dry Blasting

Compressed air and a soilid medium like Glass, Aluminium Oxide or even Crushed Walnut Shell’s are used to quickly clean surfaces back to a finish you require. From a “bright” finish for reassemly to “matt” ideal for paint adhesion.

Degreasing

We have a specialist degreasing service, ideal if you’re looking to save cleaning time on an engine rebuild or do not require blasting.

Ultrasonic Wash

Ideal if you have areas that are inaccessible, small airways, or intricate or complex shapes. this process will gently remove contamination from areas where blasing cannot reach or parts that are too delicate.

Chemical Dipping

If you need paint and coatings removed then could be what you need. Great for removing paint and filler from car panels where grinding would create surfage damage & blasting could distort panels and thin metal. This has many applications and we can take large items. Call for details.

What process should I ask for?

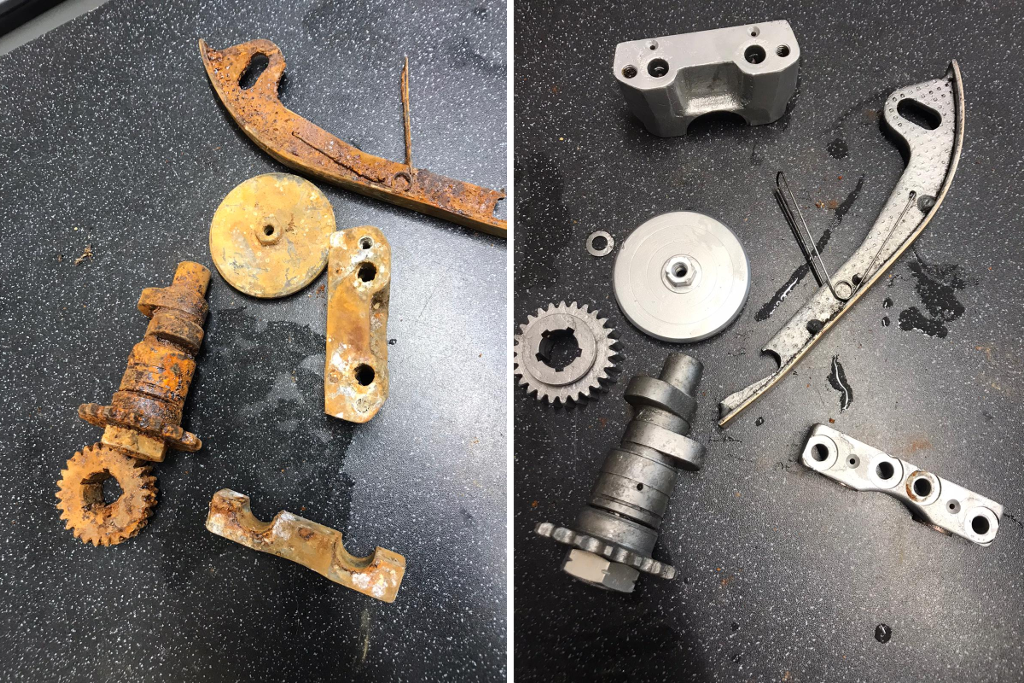

There is no hard and fast rule here. Normally we wouldn’t use Vapour Blasting for Ferrous metals but there are occasions when this is acceptable. Such as below where the requirements of the customer meant this was the right process for the job.

We can provide friendly & expert advice on the best course of action, with many years of engineering experience we’ll be able to guide you though the pitfalls.

Do You Just Do Engines?

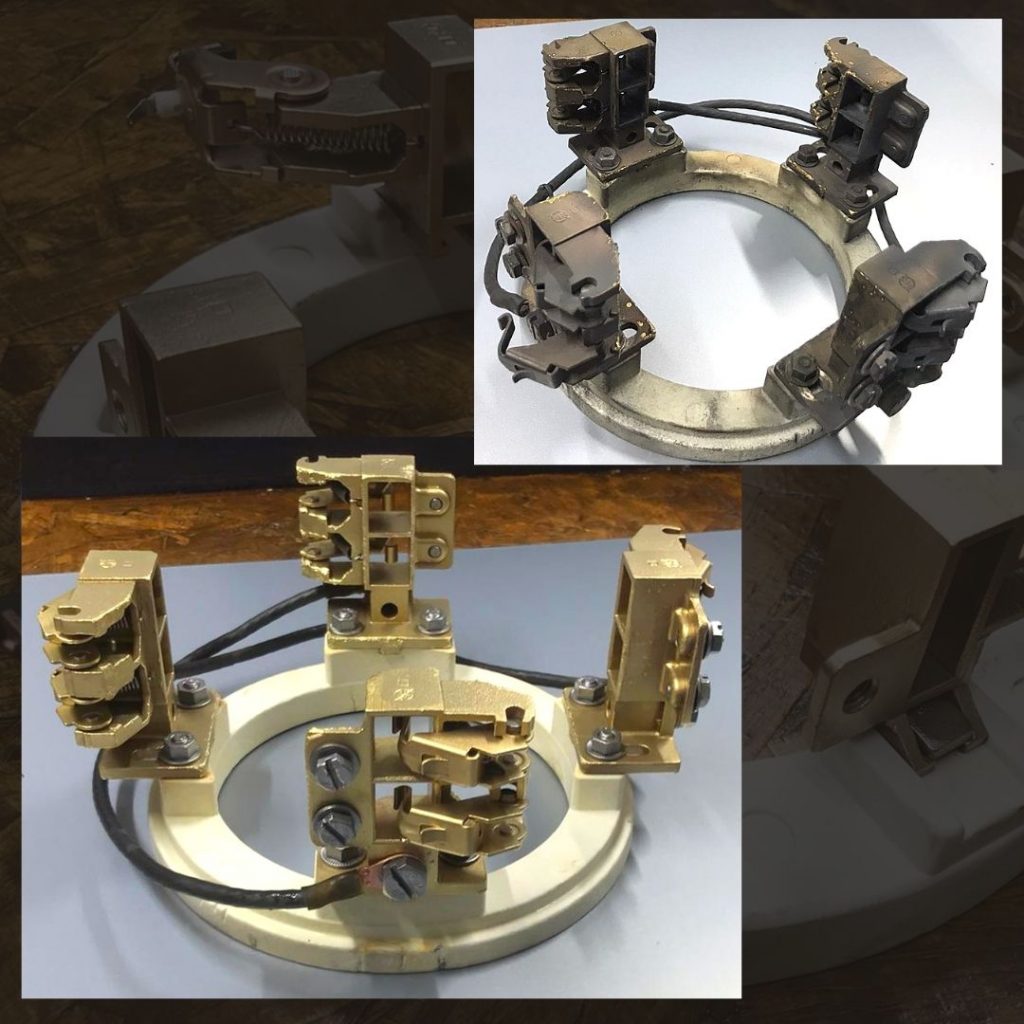

No. We have clients from a wide range of industial applications, we have cleaned copper/ceramics from electrical motors and control systems, pulleys & housings from industrial applications. In fact all manor of items. Our experience allows us to select the correct process or range of processes to get the results needed.

Are we missing something?

We are always expanding our range of services so if there is something you need which is not here give us a call. We may be able to help you or maybe you may be able to help us!